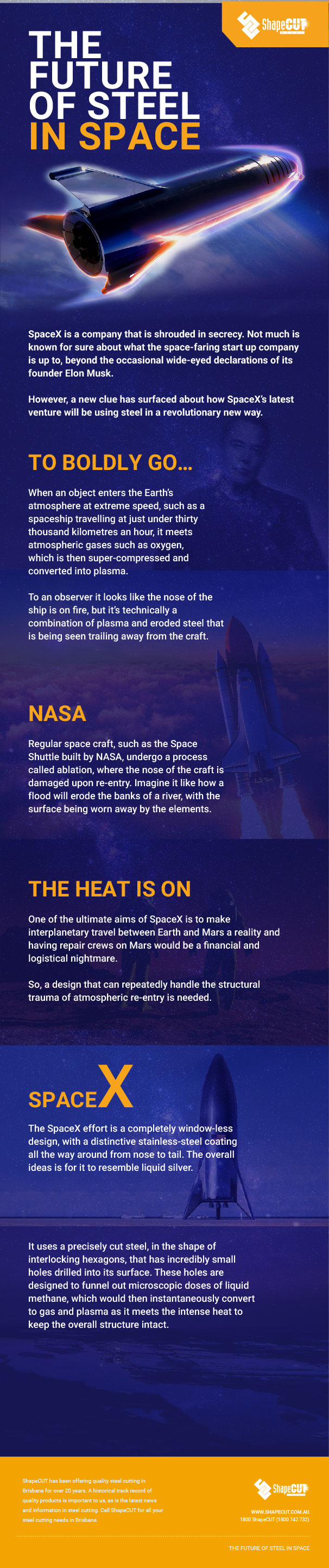

SpaceX is a company that is shrouded in secrecy. Not much is known for sure about what the space-faring start up company is up to, beyond the occasional wide-eyed declarations of its founder Elon Musk. However, a new clue has surfaced about how SpaceX’s latest venture will be using steel in a revolutionary new way.

To boldly go…

On the front cover of the April 2019 issue of the long-running engineering periodical Popular Mechanics, we see an official render of a sleek, shiny and completely stainless steel SpaceX Starship re-entering Earth’s atmosphere. It’s a clear demonstration of the new type of heat shield in action, comprised of a newly-designed skin of stainless steel hexagons using a method known as transpiration cooling.

When an object enters the Earth’s atmosphere at extreme speed, such as a spaceship travelling at just under thirty thousand kilometres an hour, it meets atmospheric gases such as oxygen, which is then super-compressed and converted into plasma. To an observer it looks like the nose of the ship is on fire, but it’s technically a combination of plasma and eroded steel that is being seen trailing away from the craft.

It’s how the surface of the spaceship handles this process that is a big part of what makes SpaceX’s effort so unique. The company is aiming to make a vessel capable of immediate re-use upon landing and refuelling to make space travel easier. Regular space craft, such as the Space Shuttle built by NASA, undergo a process called ablation, where the nose of the craft is damaged upon re-entry. Imagine it like how a flood will erode the banks of a river, with the surface being worn away by the elements. It’s amazing how only a few minutes of re-entry can wear away entire sections of the spaceship, making it effectively unusable until repaired or replaced.

The heat is on

The Space Shuttle used tiles of insulating material that were designed to break away from the ship during re-entry when they were damaged, which meant that every Space Shuttle mission required an extensive reworking process between each mission. One of the ultimate aims of SpaceX is to make interplanetary travel between Earth and Mars a reality and having repair crews on Mars would be a financial and logistical nightmare. So, a design that can repeatedly handle the structural trauma of atmospheric re-entry is needed.

Testing Starship heatshield hex tiles pic.twitter.com/PycE9VthxQ

— Elon Musk (@elonmusk) March 17, 2019

The SpaceX effort is a completely window-less design, with a distinctive stainless-steel coating all the way around from nose to tail. The overall ideas is for it to resemble liquid silver. It uses a precisely cut steel, in the shape of interlocking hexagons, that has incredibly small holes drilled into its surface. These holes are designed to funnel out microscopic doses of liquid methane, which would then instantaneously convert to gas and plasma as it meets the intense heat to keep the overall structure intact. How they work in practice will be something we won’t know for sure until the machines are up in the air, but Musk assures people that the process has undergone rigorous testing.

At ShapeCUT we love seeing the future of steel engineering taken to the next level, and we can’t wait to see how SpaceX’s venture fares. Whether it’s making rockets or something a bit more down-to-Earth, ShapeCUT has the tools and experience to make your next project a reality.

Images: Teslarati

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

©2024 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap