“Cutting-Edge Trends in Stainless Steel and Aluminium Profile Cutting: What to Expect in 2024“

As we step into the future, the world of stainless steel and aluminium profile cutting is evolving at a rapid pace. In 2024, innovation takes center stage, bringing us exciting trends that promise to redefine the industry. At ShapeCUT, we’re committed to staying at the forefront of these developments, and we’re thrilled to share five key trends that are set to revolutionize steel and aluminium profile cutting and laser cutting this year.

TREND 1: A LEAP IN PRECISION

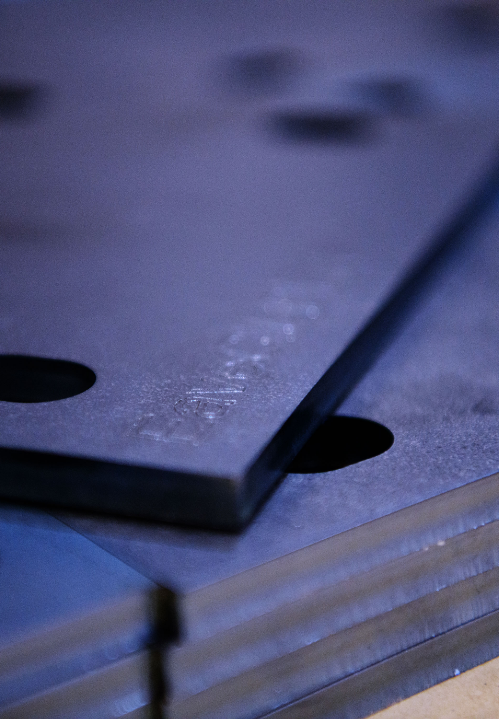

In the ever-evolving landscape of steel and aluminium profile cutting, one key trend is the remarkable leap in precision. This progress is primarily driven by the continuous advancements in laser cutting technology, which are set to redefine the very essence of meticulous craftsmanship. As we step into this exciting future, you can rest assured that ShapeCUT, armed with cutting-edge equipment and expertise, is at the front of this precision revolution. Our commitment goes past just accuracy; it extends to the realm of artistry, enabling you to materialize designs that were once considered unattainable.

Imagine the intricate lacework of steel, the delicate contours of aluminium, or the fine-grained details of a sculpture—all achieved with a level of precision that not only meets but exceeds your expectations. The laser cutting capabilities we offer are not limited by industry; whether you’re venturing into the marine, medical, automotive, or architectural sectors, the precision of our cuts will leave you astounded. As the intricacy of your projects continues to soar, ShapeCUT stands ready to transform your vision into tangible reality.

TREND 2. SUSTAINABLE CUTTING SOLUTIONS

As sustainability becomes increasingly important, the steel and aluminium industry are embracing eco-friendly practices. In 2024, we’ll witness a surge in demand for sustainable cutting solutions. At the front of this trend, is a range of technologies to minimize waste, reduce energy consumption, and promote environmentally friendly processes.

In the landscape of steel and aluminium profile cutting, the year 2024 marks an important time where sustainability takes center stage. The steel and aluminium industry is undergoing a profound transformation, aligning itself with eco-conscious practices as the demand for sustainable cutting solutions is set to surge. ShapeCUT, with its unwavering commitment to innovation, is already moving with this transformative trend.

In 2024, we’re proud to offer technologies that not only deliver high-quality cuts but also minimize waste, reduce energy consumption, and promote eco-friendly processes throughout the entire steel and aluminium profile cutting journey. When you choose ShapeCUT’s services, you’re not just investing in precision and excellence; you’re actively contributing to a greener and more sustainable future for generations to come.

TREND 3. AI-ASSISTED PROGRAMMING

In the rapidly evolving landscape of steel and aluminium profile cutting, the integration of artificial intelligence (AI) in the year 2024 represents a remarkable leap towards precision and efficiency. AI-assisted programming is revolutionizing the way cutting and shaping processes are optimized. Advanced AI algorithms are now harnessed to analyze a wealth of data, including intricate CAD models and real-time sensor feedback, allowing for dynamic adjustments in cutting parameters. This intelligent approach not only ensures each cut is precise but also maximizes efficiency, significantly reducing material waste and energy consumption along the way.

Imagine a process where every move of the cutting tool is guided by a digital brain, constantly learning and adapting to the material’s characteristics. This level of sophistication ensures that no resource is squandered, as each cut is fine-tuned to perfection. From intricate designs in architectural elements to precision components for marine engineering, AI-assisted programming sets new standards for quality and sustainability.

The implications of AI in steel and aluminium profile cutting go beyond mere efficiency; it embodies a forward-thinking commitment to reducing our environmental footprint. By minimizing material waste and optimizing energy usage, AI-assisted programming aligns perfectly with the industry’s growing focus on sustainability. As we venture into 2024 and beyond, we invite you to explore the vast potential of AI in profile cutting, where innovation meets responsibility, and every cut contributes to a greener, more efficient, and precise future.

TREND 4: CUSTOMISATION AT IT’S BEST

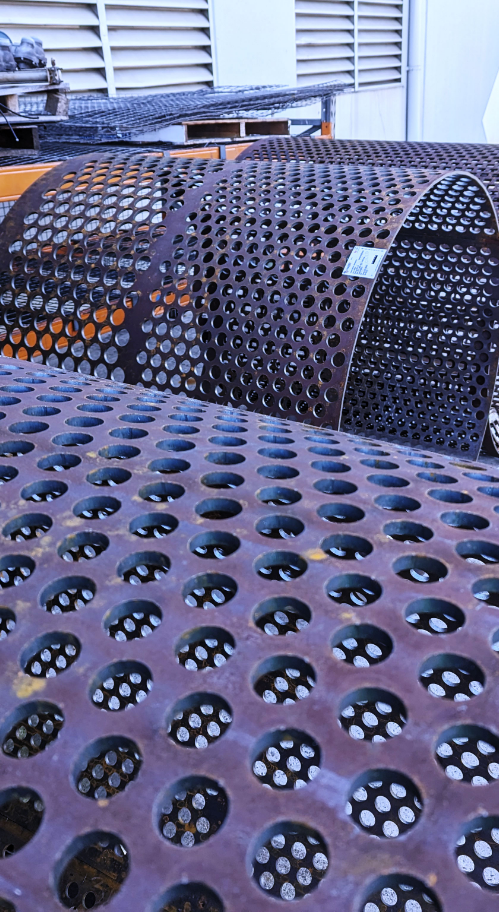

Personalization is key in 2024, and steel and aluminium profile cutting are no exception. Customers will demand tailor-made solutions to meet their unique needs. ShapeCUT is ready to cater to this trend, offering custom profile cutting, beveling, drilling, machining, rolling, stud welding, and aluminium processing services. Our team will work closely with you to bring your specific ideas and designs to life.

In the industrial landscape of steel and aluminium profile cutting in 2024, customization emerges as the standout benchmark of excellence. In an time when personalization reigns supreme, it’s clear that one-size-fits-all solutions no longer hold fast. Customers are seeking tailor-made solutions to align precisely with their unique needs and visions. Here at ShapeCUT, we recognize the significance of this trend, and we stand ready to lead the charge by offering comprehensive, custom services that encompass profile cutting, beveling, drilling, machining, rolling, stud welding, and steel and aluminium processing.

What sets ShapeCUT apart in this era of personalization is our constant commitment to making your ideas come to life. Our team is not just skilled technicians; they are dedicated craftsmen & women who understand the art of translating your specific concepts into tangible reality. Whether it’s designing intricate architectural components, crafting precision-engineered parts for industrial machinery, or creating bespoke sculptures that transcend the ordinary, we work closely with you to ensure that every detail is meticulously executed. As we embark on this journey of customization in 2024 and beyond, ShapeCUT invites you to explore the vast scope of possibilities where your unique ideas and designs take center stage.

TREND 5: ENHANCED MATERIAL COMPATIBILITY

In the dynamic landscape of steel and aluminium profile cutting in 2024, enhanced material compatibility emerges as a game-changing trend. This year marks a significant shift as the industry gears up to accommodate a wider range of materials, pushing the boundaries of what’s achievable in project design and execution.

Traditionally, steel and aluminium have been the cornerstones of our industry, offering remarkable versatility and durability. However, it’s time to look beyond the conventional, embracing exotic alloys and composite materials that were once considered challenging to work with. This expansion in material compatibility paves the way for a new era of innovation. Whether you’re envisioning futuristic architectural elements, marine components with exotic alloys, or revolutionary advancements in manufacturing, ShapeCUT’s will help you to explore uncharted territory, redefine project possibilities, and usher in a wave of groundbreaking designs.

As we embark on this journey of enhanced material compatibility, we invite you to dream big and push the boundaries of what’s achievable. Together, we will help craft a future where diversity in materials is the catalyst for groundbreaking innovation in steel and aluminium profile cutting.

TREND 6: ECO-FRIENDLY MATERIALS & PROCESSES

In 2024, sustainability is not just a buzzword; it’s a fundamental aspect of steel and aluminium profile cutting and shaping. As environmental concerns continue to grow, there is a significant trend towards using eco-friendly materials in the manufacturing process. ShapeCUT is at the front of this movement, offering eco-conscious project that prioritize green materials and processes.

The steel and aluminium industry is actively exploring sustainable alternatives, such as recycled metals and low-impact coatings. These materials not only reduce the carbon footprint but also contribute to a circular economy by reusing resources efficiently. With this trend, ShapeCUT enables you to embark on projects that not only deliver exceptional results but also showcase your dedication to a sustainable future. Join us in championing eco-friendly practices within the steel and aluminium profile cutting industry in 2024 and beyond.

TREND 7: ENHANCED WORKPLACE SAFETY

In 2024, the well-being of workers in the steel and aluminium profile cutting and shaping industry takes center stage. Safety has always been a top priority, but now, more than ever, there is a heightened focus on improving workplace conditions and reducing risks.

Advancements in technology and machinery are driving this trend towards increased safety. ShapeCUT is implementing safety measures that not only protect our team but also ensure our clients’ peace of mind. From automated safety interlocks and real-time monitoring systems to ergonomic workstations and advanced personal protective equipment, we are committed to creating a safer environment for everyone involved.

As the industry continues to prioritize safety, we invite you to partner with ShapeCUT for your profile cutting and shaping needs. Contact us today to learn more about our safety measures and how they can benefit your projects in 2024 and beyond. Together, we can achieve remarkable results while keeping safety at the forefront of every endeavor.

Contact ShapeCUT Today to Embrace the Future of Profile Cutting

At ShapeCUT, we’re not just keeping up with these trends; we’re leading the charge. To take advantage of these exciting developments and make your projects a success in 2024, reach out to our expert team today. Let us be your trusted partner in navigating the ever-evolving world of steel and aluminium profile cutting. Contact us now, and let’s shape the future together!

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

END.

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

©2025 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap