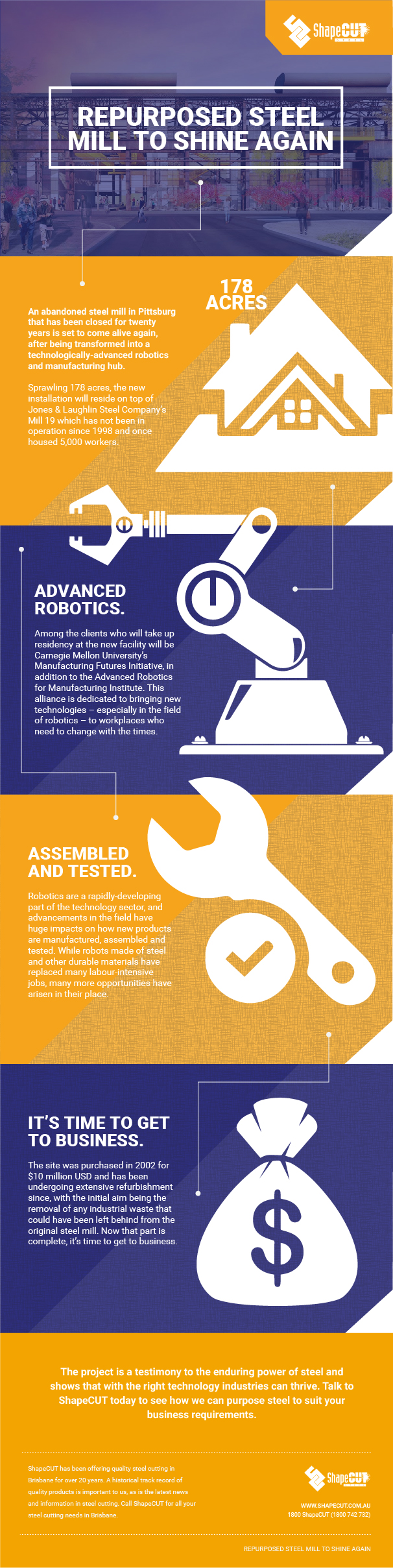

An abandoned steel mill in Pittsburg that has been closed for twenty years is set to come alive again, after being transformed into a technologically-advanced robotics and manufacturing hub.

Sprawling 178 acres, the new installation will reside on top of Jones & Laughlin Steel Company’s Mill 19 which has not been in operation since 1998 and once housed 5,000 workers. Hazelwood Green sits across from Uber’s test track, and is expected to house three dedicated buildings who are furthering the potential of robotics in never-before seen ways.

Whether or not the new manufacturing facility will churn out helpful robots like Wall-E or vengeful human-hunting machines like the Terminator has yet to be seen.

“There is possibly no other site in this country that has the potential of looking at the future and understanding where manufacturing is going to have a place,” said Mayor Bill Peduto. “It stands on the shoulders of the tens of thousands that worked on this sacred ground, and appreciates and understands that we can build from it, not take away from it.”

Among the clients who will take up residency at the new facility will be Carnegie Mellon University’s Manufacturing Futures Initiative, in addition to the Advanced Robotics for Manufacturing Institute. This alliance is dedicated to bringing new technologies – especially in the field of robotics – to workplaces who need to change with the times. They also train the staff of companies who are undergoing technological process upgrades in order to give them the skills and training required to operate the new devices.

Hazelwood Green, the home of the former steel mill, was once a thriving manufacturing town with over 13,000 people calling it home. Today less than half that number remain, but the town is hoping that this new development will bring new people into its population in the future.

Robotics are a rapidly-developing part of the technology sector, and advancements in the field have huge impacts on how new products are manufactured, assembled and tested. While robots made of steel and other durable materials have replaced many labour-intensive jobs, many more opportunities have arisen in their place.

“Nearly three decades after Pittsburgh was written off as a place whose glory days were in the past, the city has reinvented itself as the center of a new economy,” said Farnam Jahanian, interim president of Carnegie Mellon University, “and our academic institutions are playing a central role in this reinvention.”

The site was purchased in 2002 for $10 million USD and has been undergoing extensive refurbishment since, with the initial aim being the removal of any industrial waste that could have been left behind from the original steel mill. Now that part is complete, it’s time to get to business.

Surrounding the Carnegie Mellon and ARM joint partnership area public parks, retail spaces and areas set aside for housing and public transit. Town planners also see the new development as an incentive for the public to get access to the nearby Monongahela River, which has a steady flow of cargo boats going through it daily.

The project is a testimony to the enduring power of steel and shows that with the right technology industries can thrive. Talk to ShapeCUT today to see how we can purpose steel to suit your business requirements.

Images: PennLive

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

©2024 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap