The race to make every industry on the planet as ecologically-sound as possible is definitely on, and the steel industry is no exception. Since the process of steelmaking requires an incredible amount of energy and heat to work, there is a great demand to reduce its impact on the environment.

Thankfully, engineers are working on several proven technologies that can reshape the way steel is made and processed which can serve as models for manufacturing plants around the world.

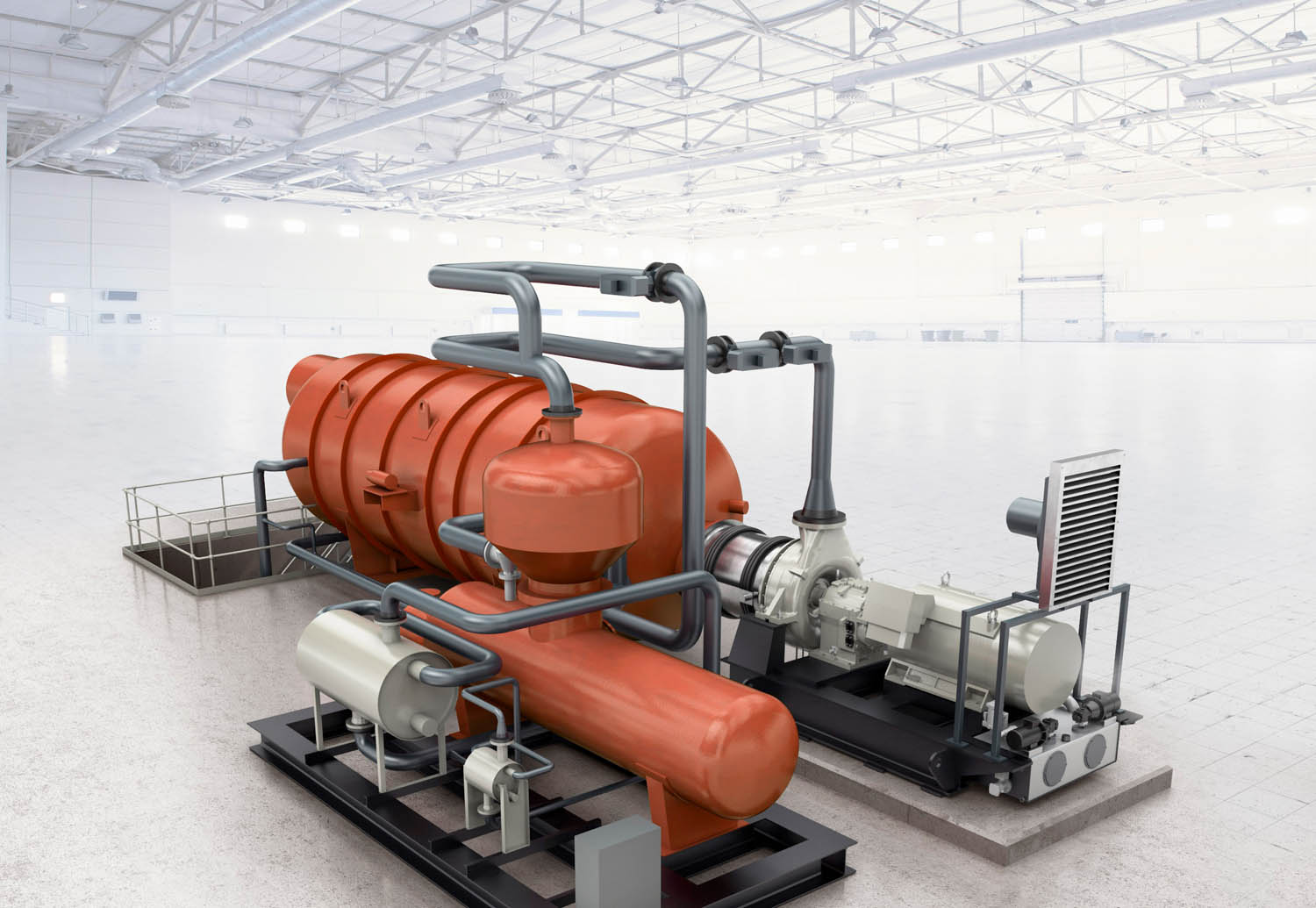

Organic Rankine Cycle Turbines

In Brescia, Northern Italy, a new technology called Organic Rankine Cycle (ORC) turbines are being put to use at the Ori Martin steel plant. This is a system aimed at manufacturing facilities that produce a lot of waste heat during their regular operations, which the steel industry does in vast quantities.

Put simply, the system recovers the heat and gases that rise up above the steel forge and pushes it through a steam turbine system, similar to that found in power plants to generate electricity. This method, which uses an organic fluid instead of steam generated from water, makes enough power to keep between 700 to 2,000 households fully supplied depending on the time of the year. It’s enough to keep 10,000 tons of carbon dioxide out of the skies every year, which is a tremendous achievement.

Recycling

The importance of recycling cannot be understated. Recycling is another way in which the steel industry can contribute to a cleaner and more sustainable future. One of the great things about steel is that it can be completely recycled with no loss of structural integrity. This means that manufacturers will often reuse scrap steel as an additional resource, which means less steel needs to be made in the first place.

However, even when using recycled materials, the steel production process still generates plenty of waste in the form of dust and mill scale. When you’re dealing with large-scale operations like steelmaking, these waste products can become a big problem.

The good news is that these elements, too, can be worked around. For example, by using a network of liquid cooling pipes around the foundry, steel bars are cooled as they emerge to prevent excess waste.

Additionally, gas cleaning removes dust from exhaust systems to help the plant reach its emission limits. An incredible 10 to 25 kilograms of dust accumulates in exhaust systems from every metric ton of steel produced, which is then expelled into the greater atmosphere. By dedusting, particles are removed from the exhaust flume before they reach open air.

Smart Plants

One way to reduce costly errors, which in turn can result in environmental mistakes, is to remove the human factor as much as possible. By making the different components of a steel mill use automation technology, new efficiencies can be discovered and taken advantage of. Not only will this reduce costs but it will result in a cleaner method of production. New advances in automatic such as artificial intelligence and machine learning will experiment with new methods that have not been devised before.

At ShapeCUT we pride ourselves at being on the cutting edge of steel – literally. Contact ShapeCUT today to explore our steel cutting services and much more.

Images: Phys.org, SteelGuru, Medium

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

Metal Processing Services

©2025 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap