Steel is such a strong and versatile construction material that, to many people, it may even appear to be indestructible. However, steel surfaces need to be extensively treated before they can be used.

If left untreated, steel surfaces are prone to the corrosive effects of rust, dust, grime and other contaminants that can come in during the manufacturing process.

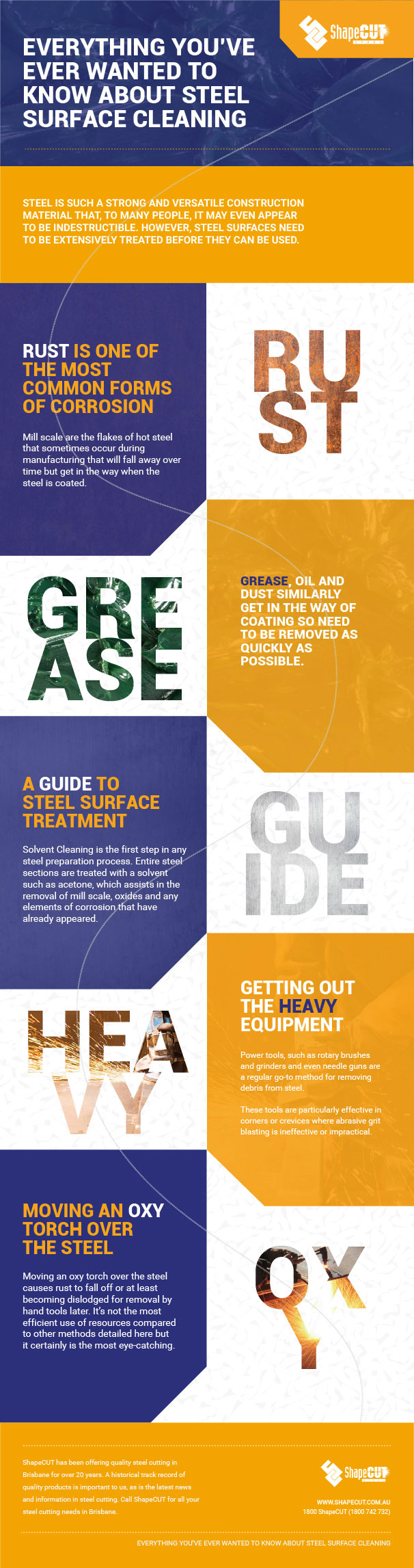

Contaminants – or foreign material – can, if left unchecked, destroy the structural integrity of steel. Rust is one of the most common forms of corrosion, and pitted corrosion can make whole sections of steel completely unfeasible. Mill scale are the flakes of hot steel that sometimes occur during manufacturing that will fall away over time but get in the way when the steel is coated. When the Mill scale is removed it leaves uncoated sections open to contamination. Grease, oil and dust similarly get in the way of coating so need to be removed as quickly as possible.

A guide to steel surface treatment

There are many methods to preparing steel surfaces for treatment, and we will detail the most popular and effective ones.

Solvent Cleaning is the first step in any steel preparation process. Entire steel sections are treated with a solvent such as acetone, which assists in the removal of mill scale, oxides and any elements of corrosion that have already appeared.

A popular method of surface treatment is abrasive grit blasting. Once the steel is cleaned of any oil and grease, it’s passed through a shot-blasting machine. This device shoots a compressed load of abrasive materials, which forcefully push against any foreign material. A brush inside the machine sweeps the steel until it’s clean.

An alternative version of this method is wet abrasive blasting cleaning. Instead of using a shot of abrasive material, this technique uses water. Imagine a giant power hose and you’re on the right track. This method is recommended for instances where lead-based paints and water-soluble materials have been found on the steel surface.

Getting out the heavy equipment

Power tools, such as rotary brushes and grinders and even needle guns are a regular go-to method for removing debris from steel. These tools are particularly effective in corners or crevices where abrasive grit blasting is ineffective or impractical.

For something more hardcore for structural steel, there’s Acid pickling. This method involves lowering the steel into a giant “bathtub” of inhibited acids designed to dissolve mill scale and rust. The size and complexity of this task might appear over the top but it’s certainly effective.

A more flamboyant method is using fire. Moving an oxy torch over the steel causes rust to fall off or at least becoming dislodged for removal by hand tools later. It’s not the most efficient use of resources compared to other methods detailed here but it certainly is the most eye-catching.

Zinc spray metalising is, unlike some of the methods outlined above, described as a cold process. This means that there is no chance of any steel becoming distorted, which is perfect for fine or ornate pieces such as fences or steel-based art sculptures. It also has the advantage over other methods for providing a spectacular smooth finish. Zinc spray is affixed to the steel within seconds after a shot blast process. The zinc is melted by an electric spray or gas flame gun to make it an ideal solution for a protective barrier.

Just as there are a multitude of steel surface cleaning methods, there’s an almost infinite array of uses for steel in every shape and size. At ShapeCUT, we’ve seen them all and can customise steel for any purpose you can imagine. Contact ShapeCUT today to see how we can help your business.

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

Metal Processing Services

©2025 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap