Plasma Cutting in Modern Metal Processing: A Look into ShapeCUT’s Pioneering Services

In today’s high-speed, precision-driven world of metal processing, plasma cutting stands out as one of the most innovative and transformative techniques. No company epitomizes the mastery of this technology quite like ShapeCUT. In this article, we’ll be exploring the intricate world of plasma cutting and how ShapeCUT’s cutting-edge services are revolutionizing the future of metal fabrication.

What is Plasma Cutting

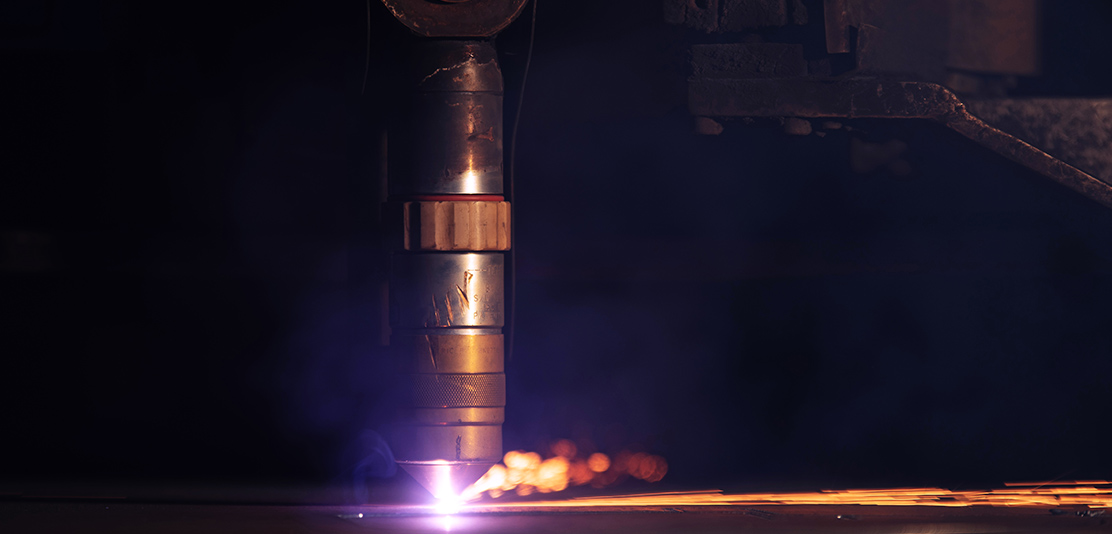

At its core, plasma cutting is the process of cutting through electrically conductive materials by using an accelerated jet of hot plasma. Materials commonly handled include steel, stainless steel, aluminium, brass, and copper, among others. The strength of plasma cutting lies in its precision, efficiency, and versatility.

ShapeCUT’s Plasma Cutting Excellence

ShapeCUT, has built a reputation for impeccable precision by realising the full potential of plasma cutting technology and making available all the various services it offers. Including the following:

High-Speed Cuts:

Plasma cutting, when done right, is remarkably fast. ShapeCUT’s equipment and expertise ensure rapid, yet accurate, production.

Versatile Fabrication:

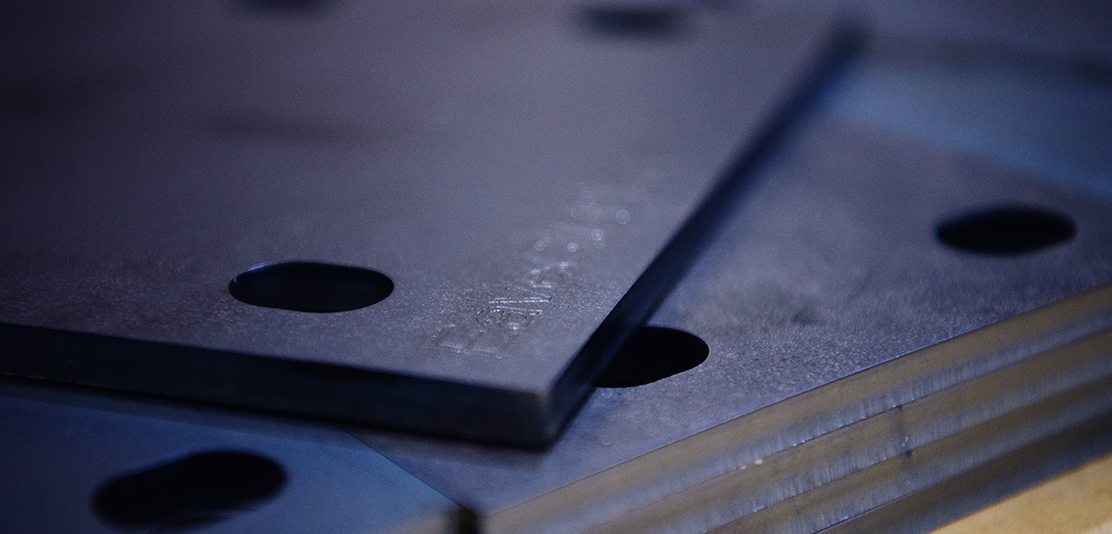

Whether it’s intricate designs on thin sheets or heavy-duty tasks on thicker materials, ShapeCUT’s plasma cutting services can handle it all.

Clean Edges:

One of the biggest challenges in metal fabrication is ensuring smooth edges. With ShapeCUT’s advanced plasma systems, the finish is often so smooth that it requires little to no secondary finishing.

The Vital Role in Australian Steel and Aluminium Processing

Australia’s industrial sector is expansive, and its demand for precision metal products is ever-growing. Plasma cutting, especially services rendered by leaders like ShapeCUT, play an indispensable role in fulfilling this need.

The technique’s versatility ensures that it caters to a variety of sectors. From the construction of monumental skyscrapers, intricate metal artworks, to the detailed components required in the automobile and aerospace sectors, plasma cutting finds its applications everywhere.

When Would You Need a Good Plasma Cutter? Examples of Work:

Art Installations: Modern art often incorporates metal, and the precision of plasma cutting allows artists to realize even the most intricate designs.

Automotive Components: Vehicles require parts that are both robust and precisely fabricated. Whether it’s the chassis or engine components, plasma cutting offers the required precision.

Aerospace Industry: When it comes to aircraft, precision is non-negotiable. Parts need to be perfectly shaped and weighted.

Construction: Beams, frames, and other foundational elements of structures often require the touch of a good plasma cutter.

Shipbuilding: The marine industry, particularly in Australia with its vast coastlines, relies heavily on plasma cutting for parts ranging from the hull to detailed interior components.

ShapeCUT’s dedication to pushing the boundaries of plasma cutting technology is a part of the future of metal processing. As industries across Australia and the world continue to demand precision and efficiency, the role of plasma cutting, and its masters like ShapeCUT, will only become more pivotal.

In the convergence of fire and metal, plasma cutting emerges not just as a technique, but as an art form, shaping the world, one cut at a time. Shaping the Future with Plasma

END…

Contact Us To Find Out More

We ensure a fast, exact and economical steel solution for our clients. Call our team today to discuss your steel cutting and metal processing requirements.

Get Our Newsletter

Contact details

121 Mica Street, Carole Park,

QLD, 4300, AUSTRALIA

Freecall: 1800 SHAPECUT (1800 742 732)

Telephone: (07) 3271 5600

Facsimile: (07) 3271 5454

Email: sales@shapecut.com.au

Accredited Profile Cutting

Profile Cutting

©2025 ShapeCut | Website design Brisbane by iFactory | Privacy Policy | Search | Sitemap